As someone who is still learning and exploring the vast field of Supply Chain Management (SCM), I am constantly amazed by the depth and complexity of this field. During my recent class on forecasting, I had the opportunity to delve into various critical aspects of SCM, ranging from transportation methods to inventory management, and even the integration of AI in logistics. These topics are not only fascinating but also incredibly relevant to real-world business operations.

One of the highlights of my learning journey was a final project where I conducted a forecast simulation for a Dairy Queen store. This project was both challenging and enlightening, providing me with practical insights into stock optimization and sales forecasting. Through this experience, I gained some knowledge of the factors that influence supply chain efficiency and the importance of accurate data analysis.

With this article, my goal is to share some of the key lessons and insights I have gained so far in my SCM journey. While I still have much to learn, I hope this piece provides valuable information and sparks further interest in the critical topics of forecasting and supply chain management.

Key Concepts in Supply Chain Management

Supply Chain Management (SCM) is a multifaceted discipline that involves the coordination of various activities to ensure the efficient movement of goods and services. Here are some key SCM concepts, along with real-life examples to illustrate their practical applications:

- Transportation Methods Transportation is a crucial element of SCM as it involves the physical movement of goods from one location to another. Different transportation methods, such as road, rail, air, and sea, each have their advantages and limitations. For instance, road transport is flexible and ideal for short distances, while sea transport is cost-effective for large volumes of goods over long distances. Understanding the right transportation method for your specific needs is key to minimizing costs and ensuring timely delivery.

Real-Life Example:

Amazon: Amazon uses a combination of transportation methods, including trucks, planes, and drones, to ensure fast and reliable delivery. Their Prime Air service aims to deliver packages within 30 minutes using drones, exemplifying the innovative use of transportation methods to enhance customer service.

- Inventory Management: Stock-Outs Inventory management involves maintaining the optimal level of stock to meet customer demand without overstocking or understocking. Stock-outs, which occur when inventory is depleted, can lead to lost sales and dissatisfied customers. Effective inventory management requires careful planning and the use of forecasting techniques to predict demand accurately. Implementing systems that provide real-time inventory data can help prevent stock-outs and ensure that products are always available when needed.

Real-Life Example:

Walmart: Walmart’s use of sophisticated inventory management systems allows it to keep track of its vast inventory in real-time. By using technologies like RFID (Radio-Frequency Identification) tags, Walmart can efficiently manage stock levels across its numerous stores, ensuring product availability and reducing wastage.

Apple: During the launch of new iPhone models, Apple often faces stock-outs due to high demand. To mitigate this, Apple employs pre-order systems and adjusts production schedules to manage inventory levels and reduce the frequency of stock-outs.

- Warehouse Management Efficient warehouse management ensures that goods are stored, managed, and retrieved in an organized manner, reducing delays and operational costs. Key aspects include layout optimization, inventory tracking, and the use of technology such as warehouse management systems (WMS) and automated guided vehicles (AGVs). By optimizing warehouse processes, businesses can improve order fulfillment rates and reduce the time products spend in storage.

Real-Life Example:

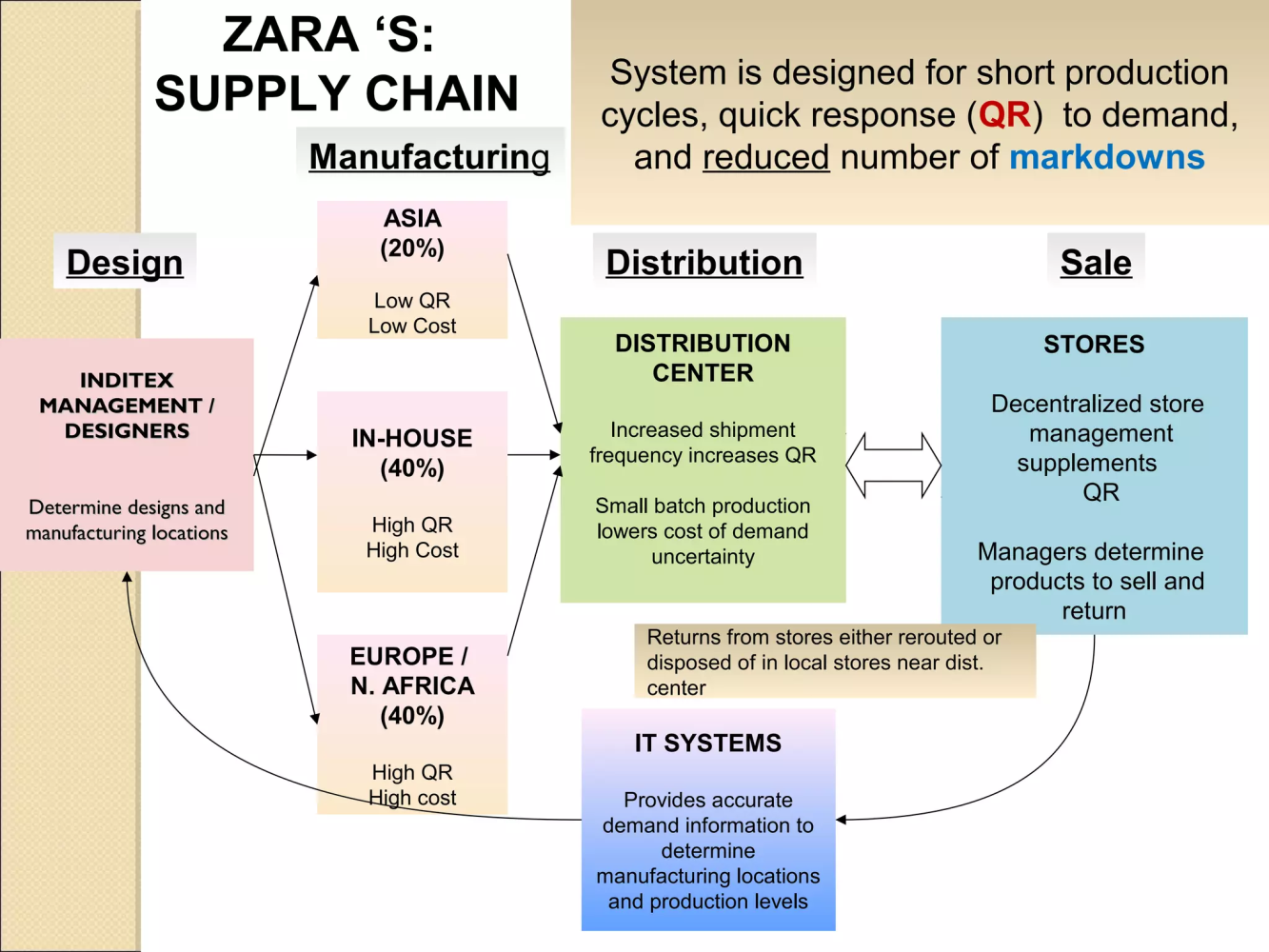

Zara: Zara’s highly efficient warehouse management system enables it to quickly distribute new fashion trends to its stores worldwide. Their warehouses are strategically located and equipped with advanced automation technologies to expedite the sorting and shipping process, ensuring that new collections reach stores rapidly.

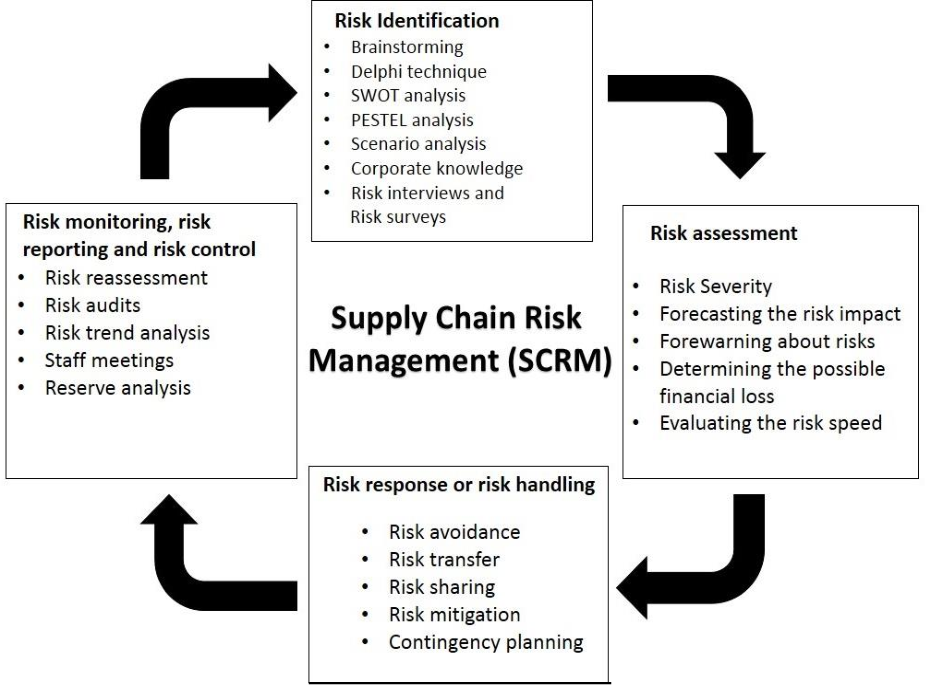

- Risk Management Risk management in SCM involves identifying, assessing, and mitigating risks that can disrupt the supply chain. These risks can include natural disasters, supplier failures, geopolitical issues, and cyber threats. Effective risk management strategies include diversifying suppliers, maintaining safety stock, and implementing robust cybersecurity measures. By proactively managing risks, companies can enhance supply chain resilience and ensure continuity of operations.

Real-Life Example:

Toyota: After the 2011 earthquake and tsunami in Japan, Toyota revamped its risk management strategies. They diversified their supplier base and established more robust contingency plans to mitigate the impact of future disruptions on their supply chain operations.

- Logistics Network The logistics network encompasses all the interconnected elements involved in moving goods from suppliers to customers. This includes transportation, warehousing, distribution centers, and inventory management. Designing an efficient logistics network requires analyzing factors such as transportation costs, delivery times, and customer service levels. An optimized logistics network can lead to significant cost savings and improved customer satisfaction.

Real-Life Example:

FedEx: FedEx’s extensive logistics network is designed to optimize the delivery process. With strategically located hubs around the world, FedEx ensures quick and efficient movement of parcels, leveraging advanced tracking systems to provide real-time updates to customers.

UPS: UPS has a vast logistics network that includes air and ground transportation, along with a network of distribution centers. Their integrated logistics solutions help businesses streamline their supply chain operations and improve delivery efficiency.

Understanding and effectively managing these key concepts is crucial for the success of any supply chain. Each element plays a vital role in ensuring that goods and services are delivered efficiently, cost-effectively, and on time. By focusing on these areas, businesses can create a more resilient and responsive supply chain capable of adapting to changing market conditions and customer demands.

The Role of AI in Logistics

Artificial Intelligence (AI) is revolutionizing the logistics industry, bringing unprecedented efficiencies and capabilities to supply chain operations. By automating routine tasks, enhancing decision-making, and providing deeper insights, AI is transforming how goods are transported, stored, and delivered.

How AI is Transforming Logistics

- Predictive Analytics: AI enables predictive analytics, allowing companies to forecast demand more accurately, optimize inventory levels, and reduce waste. By analyzing historical data and identifying patterns, AI helps businesses anticipate future trends and make informed decisions.

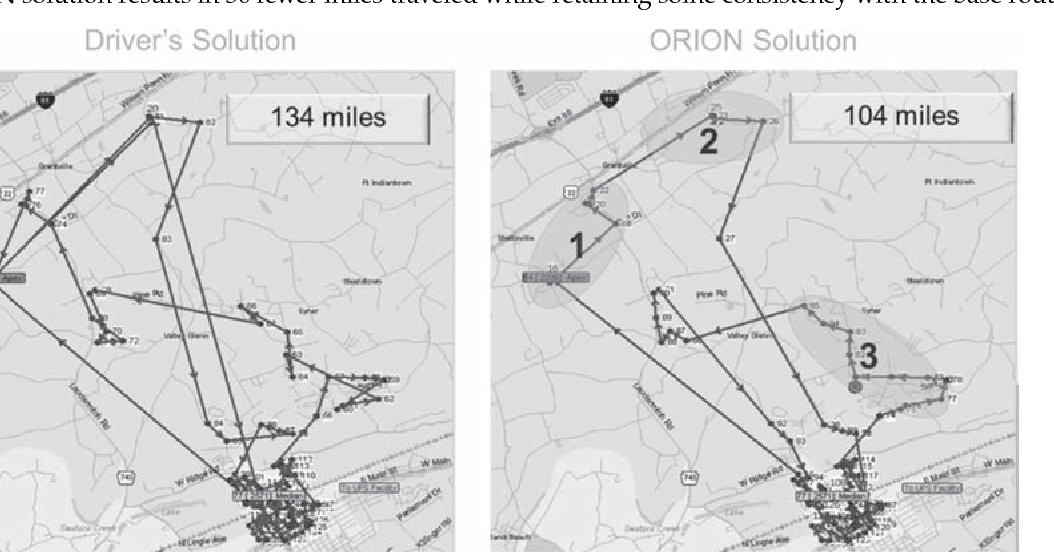

- Route Optimization: AI-powered algorithms can analyze real-time traffic data, weather conditions, and other variables to determine the most efficient delivery routes. This reduces fuel consumption, cuts down delivery times, and enhances overall operational efficiency.

- Autonomous Vehicles and Drones: AI is the driving force behind the development of autonomous vehicles and drones. These technologies have the potential to revolutionize last-mile delivery, reducing reliance on human drivers and increasing delivery speed and accuracy.

- Warehouse Automation: AI-powered robots and automated systems streamline warehouse operations, from sorting and picking to packing and shipping. This not only increases efficiency but also reduces the risk of human error.

- Supply Chain Visibility: AI enhances supply chain visibility by integrating data from various sources, providing real-time insights into the status of shipments, inventory levels, and potential disruptions. This allows companies to proactively address issues and maintain smooth operations.

Real-Life Applications and Examples

- Amazon Robotics: Amazon’s warehouses are equipped with AI-powered robots that assist in picking, sorting, and packing items. These robots work alongside human employees to increase efficiency and reduce order fulfillment times. By leveraging AI, Amazon can process orders quickly and accurately, ensuring timely deliveries to customers.

- UPS Orion: UPS utilizes an AI-based route optimization system called Orion (On-Road Integrated Optimization and Navigation). Orion analyzes various factors, such as traffic conditions, weather, and package delivery priorities, to determine the most efficient delivery routes. This has resulted in significant fuel savings, reduced emissions, and improved delivery times.

- DHL’s Predictive Maintenance: DHL uses AI-driven predictive maintenance to monitor its fleet of vehicles and equipment. By analyzing data from sensors and identifying patterns, AI can predict when maintenance is needed, preventing breakdowns and minimizing downtime. This ensures that DHL’s operations run smoothly and efficiently.

- JD.com’s Autonomous Delivery: Chinese e-commerce giant JD.com has implemented AI-powered autonomous delivery vehicles and drones. These autonomous systems navigate complex urban environments to deliver packages to customers. By reducing the need for human drivers, JD.com can offer faster and more cost-effective delivery services. Similar to Amazon

- Maersk’s Predictive Analytics: Shipping company Maersk employs AI to optimize its container shipping operations. AI algorithms analyze data from various sources, such as weather patterns and port congestion, to predict delays and optimize shipping routes. This helps Maersk enhance its operational efficiency and provide reliable services to its customers.

AI is fundamentally transforming the logistics industry by bringing efficiencies and capabilities to supply chain operations. From predictive analytics and route optimization to autonomous vehicles and warehouse automation, AI is revolutionizing how goods are transported, stored, and delivered. Companies that leverage AI in their logistics operations can achieve significant cost savings, improve customer satisfaction, and gain a competitive edge in the market. As AI continues to evolve, its impact on logistics will only grow, driving further innovations and advancements in the industry.

Sustainability in Supply Chain Management

While I am still on my learning journey, it’s clear that integrating sustainability into supply chain practices is essential for the future of businesses and the planet. Here’s a closer look at why sustainability matters and how the concept of the triple bottom line (People, Planet, Profit) plays a crucial role.

Importance of Sustainability

Sustainability in supply chain management is not just a trend; it’s a necessity. As global concerns about climate change, resource depletion, and social inequalities grow, companies are under increasing pressure to operate responsibly. Sustainable supply chain practices help businesses reduce their environmental footprint, improve social equity, and ensure long-term economic viability.

- Environmental Impact: Traditional supply chain activities, such as manufacturing, transportation, and warehousing, contribute significantly to environmental degradation. Adopting sustainable practices, like reducing emissions, conserving energy, and minimizing waste, helps mitigate these negative impacts. For example, companies can switch to renewable energy sources, optimize transportation routes to lower fuel consumption, and implement recycling programs.

- Social Responsibility: Ensuring fair labor practices and supporting local communities are integral to sustainable supply chain management. Companies need to ensure that their suppliers uphold human rights and provide safe working conditions. This not only helps protect workers but also enhances the company’s reputation and customer trust.

- Economic Benefits: Sustainability can drive economic benefits by improving efficiency and reducing costs. Sustainable practices often lead to innovations that enhance productivity and open up new market opportunities. Furthermore, customers and investors are increasingly favoring companies with strong sustainability credentials, making it a critical factor for long-term success.

The Triple Bottom Line: People, Planet, Profit

The triple bottom line (TBL) framework expands the traditional focus on profit to include social and environmental considerations. It emphasizes the need for a balanced approach that values people and the planet alongside profit.

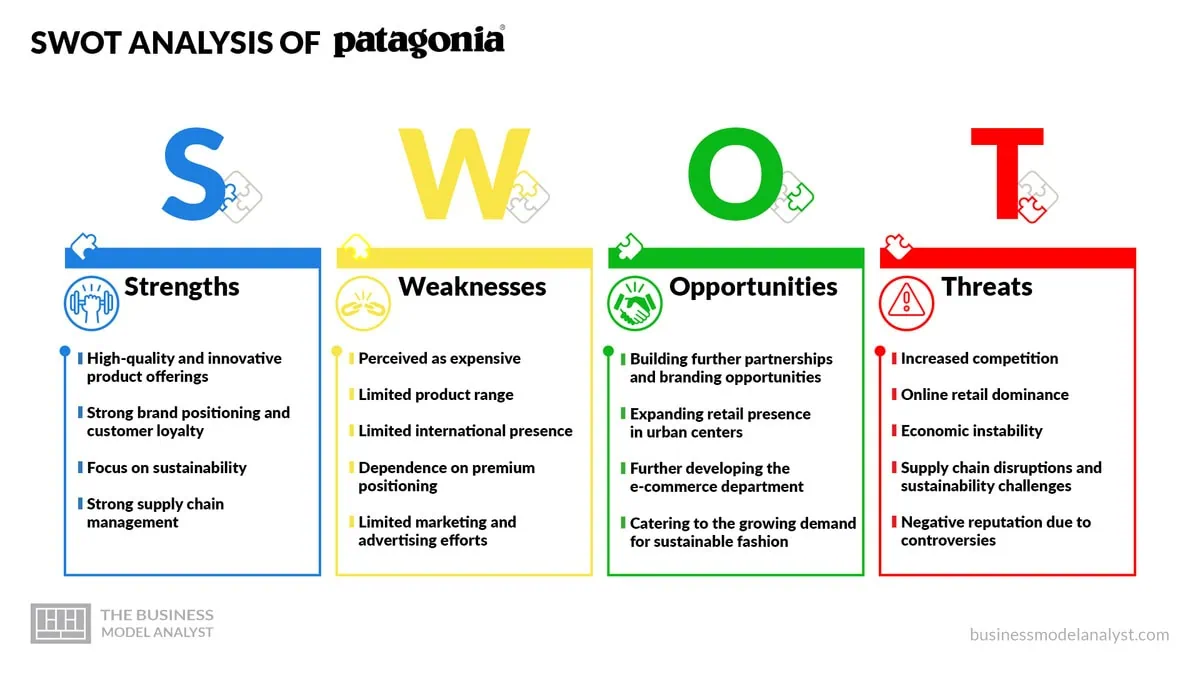

1. People: The social aspect of TBL focuses on the impact of business operations on employees, customers, and communities. Companies need to foster ethical practices, such as fair wages, safe working conditions, and community engagement. A real-life example is Patagonia, which is known for its commitment to fair labor practices and employee well-being. By investing in people, businesses can build a loyal workforce, enhance brand reputation, and create positive social change

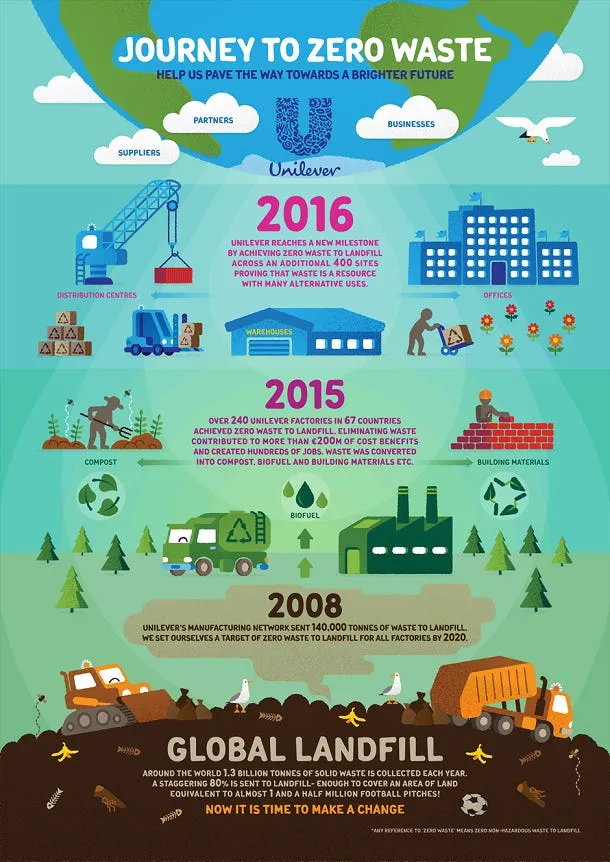

2. Planet: The environmental aspect emphasizes minimizing the ecological footprint of business activities. This involves reducing greenhouse gas emissions, conserving resources, and promoting biodiversity. For instance, Unilever has made significant strides in sustainability by sourcing raw materials responsibly and reducing its carbon footprint. Sustainable environmental practices help protect the planet for future generations and ensure the availability of resources.

3. Profit: While social and environmental responsibilities are crucial, businesses must also remain economically viable. Sustainable practices can drive profitability through cost savings, risk management, and market differentiation. For example, IKEA’s investment in renewable energy has not only reduced its environmental impact but also led to significant cost savings. Profitability ensures that companies can continue to invest in sustainability initiatives and drive long-term growth.

After the forecasting class I took on Supply Chain Management, I am increasingly aware of the importance of sustainability. The triple bottom line (People, Planet, Profit) provides a framework for achieving sustainable supply chain operations. By balancing social, environmental, and economic considerations, companies can build resilient and responsible supply chains that contribute to a better world. While there is still much to learn, the journey toward sustainability is both necessary and rewarding, offering benefits for businesses, society, and the planet.

Forecasting Methods

Forecasting is a critical component of supply chain management, allowing businesses to predict future demand and adjust their operations accordingly. In my forecasting project simulation, I had the opportunity to apply several forecasting methods to better understand their applications and effectiveness. Here are the key methods I explored:

Naïve Method

The Naïve Method is one of the simplest forecasting techniques, relying on the assumption that future values will be similar to the most recent actual values. This method is straightforward and easy to implement, making it useful for short-term forecasts and stable environments.

- Example in Project: In my Dairy Queen simulation, I started with the Naïve Method to forecast the sales of ice cream during non-peak seasons. This method helped me quickly estimate future sales based on the previous period’s sales data. While it was easy to use, I realized its limitations in accurately predicting sales during more volatile periods, such as summer or special promotions.

Cumulative Method

The Cumulative Method involves summing the historical data and using the total to predict future values. This method can provide a broader view of trends over time, but it may not be sensitive to recent changes or seasonal variations.

- Example in Project: For the Dairy Queen project, I then applied the Cumulative Method to get an overall sense of sales trends over the year. This approach helped me identify long-term patterns, but it was less effective for capturing short-term fluctuations or sudden spikes in demand.

Moving Average Method

The Moving Average Method smooths out short-term fluctuations and highlights longer-term trends by averaging a specific number of past observations. It is particularly useful for identifying underlying trends in time series data.

- Example in Project: I employed the Moving Average Method to forecast monthly ice cream sales at Dairy Queen. By averaging the sales data from the previous three months, I could generate a more stable forecast that accounted for short-term variations. This method proved more reliable than the Naïve and Cumulative methods, especially during periods of moderate sales fluctuation. I wanted to use either this method or the Qualitative Forecast Method but in the end, this is the one I ended up sticking with.

Qualitative Forecast

Qualitative forecasting involves using expert judgment and opinions to predict future events. This method is particularly useful when historical data is limited or when forecasting new products or markets. Techniques such as Delphi method, market research, and focus groups are commonly used.

- Example in Project: Since ice cream sales at Dairy Queen can be influenced by various qualitative factors such as local events, weather conditions, and marketing campaigns, I incorporated qualitative insights from managers and local experts. This helped me refine my forecasts by considering factors that quantitative methods might miss. However, I found it challenging to balance subjective opinions with objective data, highlighting the importance of integrating multiple forecasting methods.

Applying these forecasting methods in my Dairy Queen simulation project provided valuable insights into their strengths and limitations. The Naïve Method offered simplicity, the Cumulative Method provided a long-term perspective, the Moving Average Method balanced stability and responsiveness, and Qualitative Forecasting added a layer of expert judgment. Each method contributed uniquely to my understanding of demand forecasting, and the experience underscored the importance of using a combination of techniques to achieve more accurate and reliable forecasts. While I still have much to learn, this project has laid a strong foundation for my future in supply chain management and forecasting.

Case Study: Forecast Simulation for Dairy Queen

Project Description and Objectives

The Dairy Queen forecast simulation project aimed to optimize inventory levels and minimize waste at Dairy Queen location in Altoona, PA. The primary objective was to create a reliable forecast for ice cream sales for each month of 2022, taking into account various factors that could influence demand. This project not only provided practical insights into sales forecasting but also helped in improving my skills in supply chain management and demand planning.

Methodology and Tools Used

Data Collection and Analysis

- Historical Sales Data: I gathered and analyzed past sales data from the Dairy Queen location to identify trends and patterns. This data included monthly sales figures, which provided a foundation for my forecasting efforts.

- Qualitative Factors: I considered various qualitative factors such as local events, weather patterns, and demographic information. For instance, understanding the town population of Altoona (approximately 44,000 people) and the national average ice cream consumption (about 4 gallons per person per year) helped us gauge potential demand.

- Free Open Resources: I utilized publicly available data and resources, such as government demographic reports and industry publications, to supplement my analysis. This approach ensured that I had an understanding of the factors influencing ice cream sales.

Forecasting Methods

- Naïve Method: This simple method uses the sales data from the most recent period to predict future sales. It serves as a basic benchmark for comparison.

- Cumulative Mean Method: This method averages past sales data to provide a more stable forecast. It helps smooth out short-term fluctuations and highlight longer-term trends.

- Moving Average Method: This technique calculates the average sales over a specified number of periods, which helps to smooth out short-term variations and reveal underlying trends. It proved to be the most effective method for my project, despite some inherent errors.

Software and Tools

- Excel: I used Microsoft Excel for organizing data, performing calculations, and creating visualizations. Excel’s built-in functions and features allowed us to efficiently analyze sales data and apply different forecasting methods.

Key Learnings and Challenges

Key Learnings:

- Comprehensive Data Analysis: Understanding the importance of both quantitative and qualitative data in forecasting. For instance, analyzing population demographics, local events, and marketing efforts provided a holistic view of factors affecting ice cream sales.

- Method Comparison: Comparing different forecasting methods highlighted their strengths and limitations. The moving average method emerged as the most reliable for this project due to its ability to account for recent trends while minimizing the impact of outliers.

- Seasonality: Recognizing the significant impact of seasonal variations on ice cream sales and the necessity to adjust inventory levels accordingly.

Challenges:

- Accuracy vs. Uncertainty: Balancing the need for accurate forecasts with the inherent uncertainties in factors like weather conditions and local events. These elements were difficult to predict but had a substantial impact on sales.

- Integration of Qualitative Data: Effectively incorporating qualitative insights into the forecasting process was challenging but essential for creating a well-rounded forecast.

Personal Reflection

This project was a good learning experience, showing me the importance of thorough data analysis and the application of multiple forecasting methods. It also emphasized the need for continuous learning and adaptation in the field of supply chain management.

Recap of the Importance of SCM and Forecasting

Supply Chain Management (SCM) and forecasting are critical components in ensuring the efficiency and effectiveness of business operations. Accurate forecasting helps businesses optimize inventory levels, reduce waste, and meet customer demand promptly. The Dairy Queen project showed me the value of thorough data analysis and the application of various forecasting methods, providing practical insights into sales trends and helping prevent overstocking or stockouts. Understanding and anticipating market demands through forecasting is important for maintaining a competitive edge and achieving long-term success.

The Evolving Role of Technology and Sustainability

Technology continues to transform SCM, with advancements such as AI playing a pivotal role in logistics and inventory management. AI-driven solutions enhance decision-making processes, streamline operations, and improve accuracy in demand forecasting. Additionally, the emphasis on sustainability in SCM is growing, with businesses increasingly adopting practices that prioritize the triple bottom line: People, Planet, and Profit. Sustainable SCM practices not only reduce environmental impact but also contribute to social well-being and economic growth. By integrating technology and sustainability, businesses can achieve greater efficiency and resilience in their supply chains.

Stay tuned for articles on various IT and Business Administration topics, including web design, cybersecurity, supply chain management, and more, where I’ll go into the details of my projects and the tools I’ve used.

Subscribe to my newsletter to follow my journey on LinkedIn https://www.linkedin.com/build-relation/newsletter-follow?entityUrn=7200682566587195392

#SupplyChainManagement #Forecasting #AIinLogistics #Sustainability #BusinessStrategy

Feel free to share your experiences or ask questions about business planning in the comments below!